Our Products

100% Original Sublimation Embroidery Patches - The process of making customized embroidery patches – Yida

100% Original Sublimation Embroidery Patches - The process of making customized embroidery patches – Yida Detail:

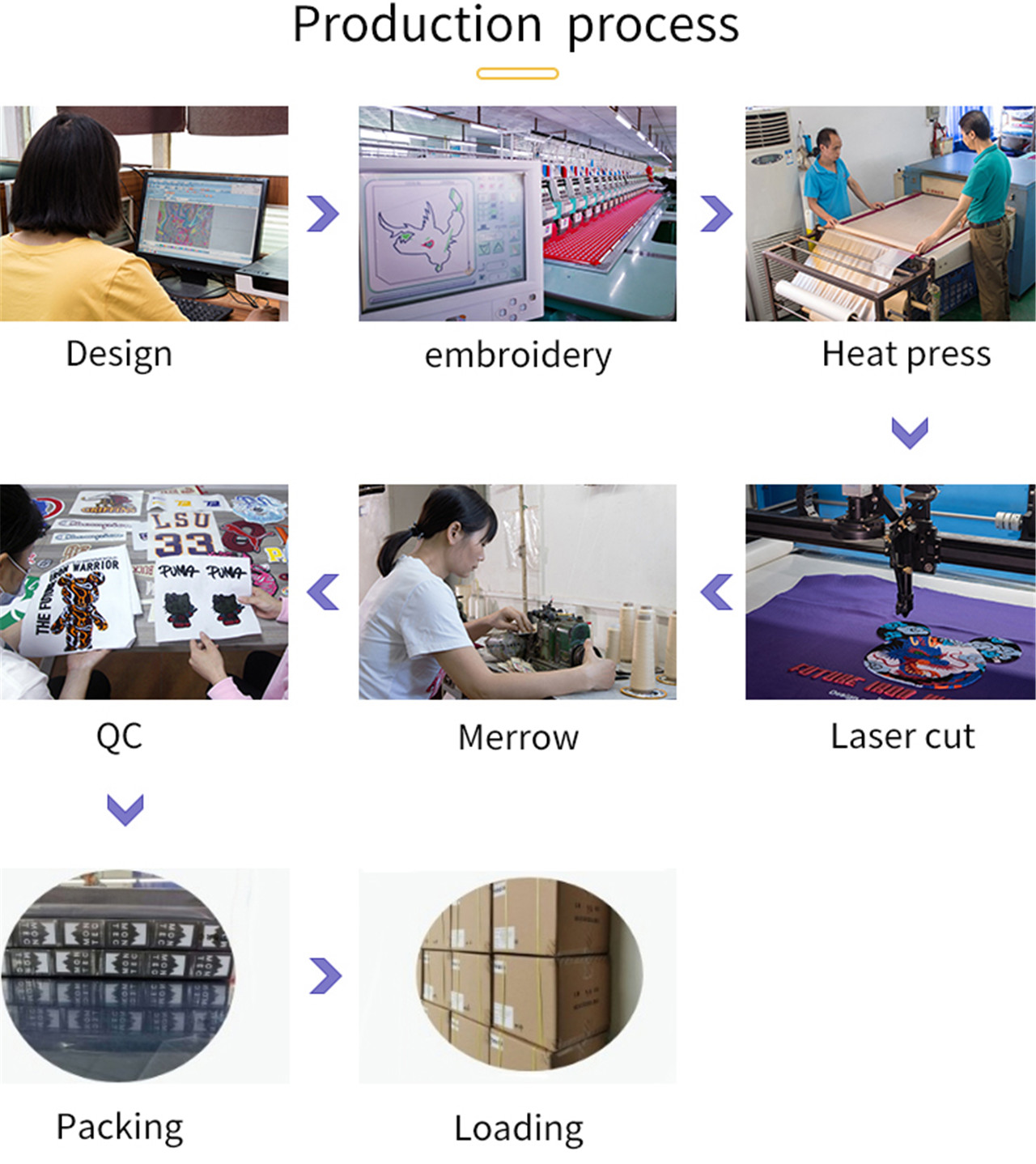

What’s the process to make the custom embroidered patches?

Embroidered badge is also an important one in all kinds of badge production, which is widely used in all kinds of leisure clothing, hat (hat badge), shoulder badge (shoulder badge) and so on. The production of embroidered badges can be customized according to samples or drawings. Mainly through scanning, artwork (if these two steps are omitted if customized according to the artwork), plate making, electric embroidery, gluing (mainly soft glue, hard glue, self-adhesive), trimming, burning edge (wrapping edge), quality inspection, packaging and other procedures.

1. First of all, the artwork is designed according to the samples and the ideas of the customers. For the reproduction of embroidery, the first draft does not have to be as correct as the finished product. We just need to know the idea or sketch, the color, and the necessary size. It is not like producing anniversary badges and commemorative coins that need to be redrawn so that they can be copied. We say “redraw” because what may be painted does not have to be embroidered. But people with certain embroidery functions are needed to copy.

2. After the customer confirms the design and color, enlarge the design pattern into a technical drawing 6 times larger, and print out the version guiding the embroidery machine according to this enlarged drawing. A loft maker should have the skills of an artist and a graphic artist. The stitching on the picture indicates the type and color of the thread used, and some requirements put forward by the printer should be considered at the same time.

3. Secondly, the typographer uses a special machine or computer to make the printing plate. From paper tape to disc, today, all kinds of printing tape, no matter what format it used to be, can be easily converted to any other format. At this stage, the human factor is important, and only those experienced plate makers with good skills can be used as badge designers. People can verify the printing tape by various means, such as on the shuttle machine, using a prototype that can make samples, so that the printer can constantly watch the embroidery being embroidered. When using a computer, the sample is made only after the flower plate belt is really tested and cut on the prototype.

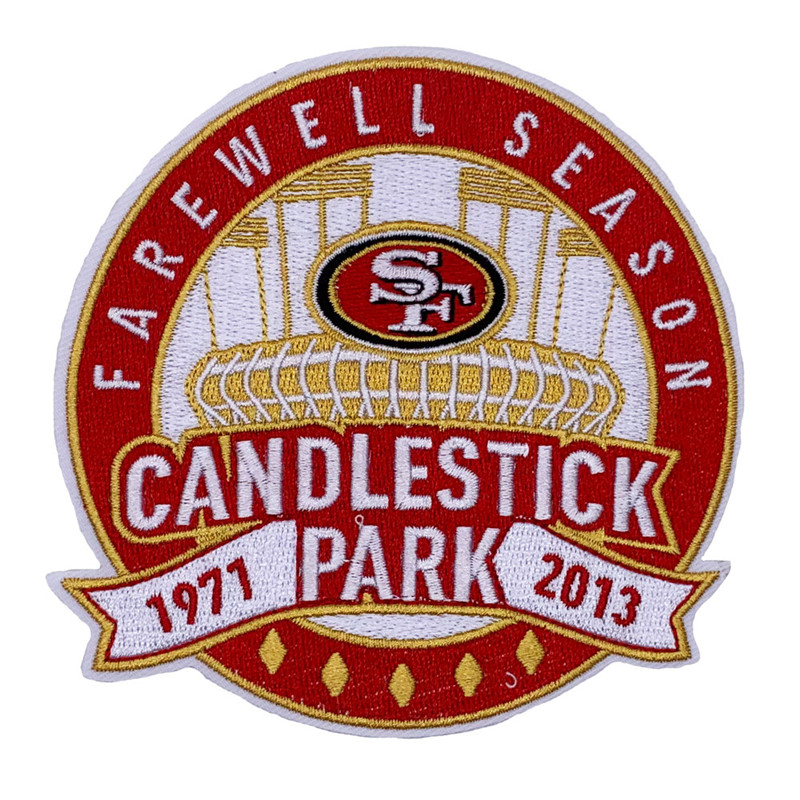

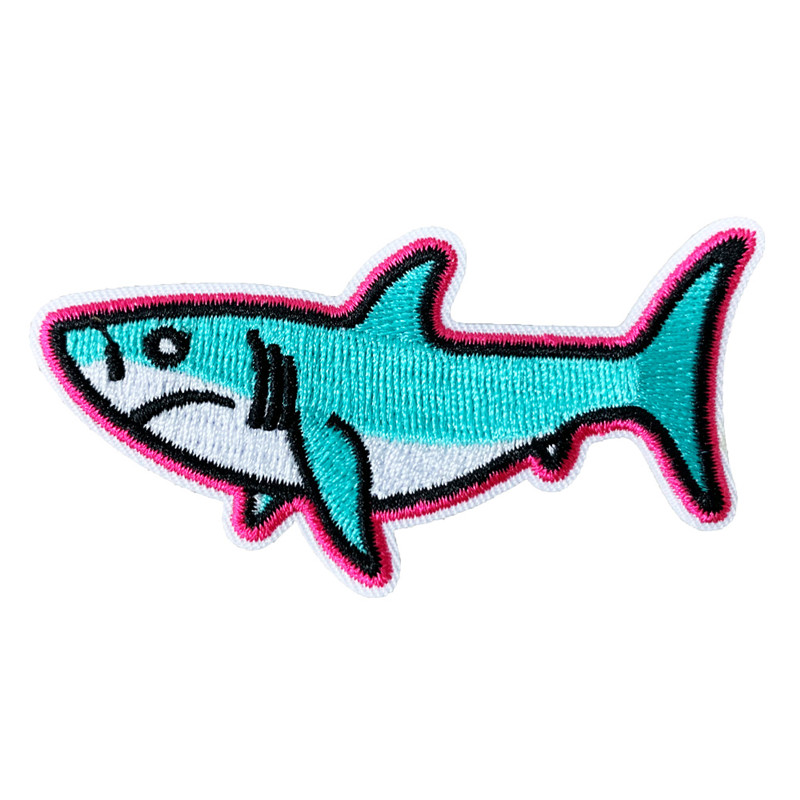

Product detail pictures:

Related Product Guide:

With advanced technologies and facilities, strict quality control, reasonable price, superior service and close co-operation with customers, we are devoted to providing the best value for our customers for 100% Original Sublimation Embroidery Patches - The process of making customized embroidery patches – Yida , The product will supply to all over the world, such as: Slovakia, Cape Town, San Francisco, Our items have been obtained more and more recognition from foreign clients, and established long term and cooperative relationship with them. We`ll supply the best service for every customer and sincerely welcome friends to work with us and establish the mutual benefit together.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed