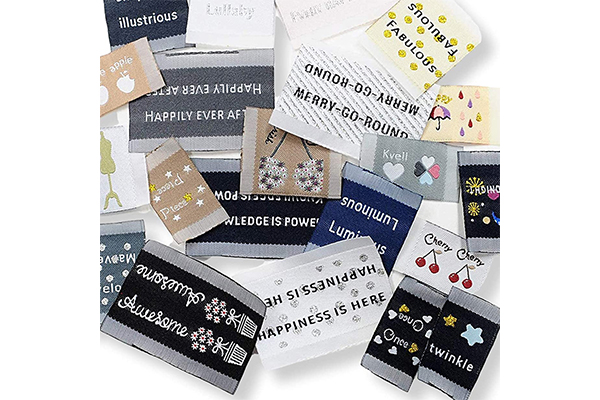

Computer woven labels are widely used, popularizing the main labels, washing labels, size labels, decorative labels, etc. on various clothing, shoes and hats, home textiles, toys, handbags, luggage, and ties. Flexible processing, can be eagerly cut, ultrasonic and laser laser into various widths (1-20CM). The woven label is divided into: woven label woven label and trimmed woven label (the trimmed woven label is divided into hot-cut woven label and super-cut woven label), and the trimmed woven label is on a special high-speed machine, like weaving. Weave it out in one piece, and cut it into strips according to the width of the target.

The hot-cut woven label is to use the heat-melting characteristics of polyester to use a very hot cutting knife to cut the entire semi-finished product into each collar label. Due to the high heat, the yarns will stick to each other when they are cut. , will not loose the edge, in the production process, due to machine failure or inattentive operation, it is easy to burn the collar label with undulating hard edges, and it is easy to scratch the skin when worn, causing discomfort, cutting edges Woven labels are generally not suitable for children’s clothing.

Ultra-cut woven label is a machine that uses an ultrasonic transducer to act on the shearing part of the product, and then presses the cutting part of the product with a tool to make it close to the ultrasonic die. The ultrasonic energy is transmitted to the shearing area through the ultrasonic die. Since the shearing area, that is, the product interval between the tool and the ultrasonic die, has a large acoustic resistance, local high temperature will be generated. In addition, due to the poor thermal conductivity of the product, it can not be distributed in time, and it gathers in the shearing area, causing the pressing surface of the product to melt rapidly and divide into two parts.

Laser cutting uses the laser beam emitted from the laser generator. Through the optical path system? Focused into a high power density laser beam irradiation condition? The laser heat is absorbed by the work piece material. The work piece temperature rises sharply? After reaching the boiling point? The material begins to vaporize and form holes ?Air flow with high pressure?As the relative position of the beam and the work piece moves.The material finally forms a slit. The process parameters (cutting speed, laser power, gas pressure, etc.) and movement trajectory during slitting are controlled by the numerical control system. The slag at the slit is blown off by a certain pressure of auxiliary gas.

Several sewing methods of clothing woven labels.There are different methods of how to sew clothing woven labels. Weaving labels are mainly divided into two types: selvage and trimming.

selvedge label:

Putting the desired logo is typically still very rich in need, but with different craftsmanship, but with different characteristics, but selvedge has many different characteristics. Soft, quite suitable for high-end clothing. Suits are of the same quality and are of the same quality. They are very similar to the most high-end noodles made in Japan, and they are also exquisitely made in Japan. Weaving labels are generally made of satin, and the edges are not very satin.

The selvage machine generally has a shuttle machine, and four colors can be used at the same time; the crochet machine can also weave the quality of various crafts, and even add transparent hook silk yarn to the wood warp, and there are needle fish silk needle machines.

In addition to the wide range of cloth labels, the total length of cloth colors, and the craftsmanship, there are also various themes of the selvage used. JB series standard is international standard, commonly used cutting.As the name suggests, on a special high-speed machine, it is woven in one piece like weaving cloth, and then cut into strips according to the width of the target. Because of the heat-melting properties of polyester, the yarns will stick to each other when they are cut, and will not scatter. It is also for this reason that the appearance and feel will be affected to a certain extent. A good machine will be better, and it will be better to use ultrasonic cutting than ordinary electric heating knives. The cloth label in strips can be directly sorted and sent to the garment factory for processing; if the requirements are strict, it still needs to be cut and folded.

Because the maximum width of this machine is 20.8cm, that is to say, labels of this width can be woven, and various shapes can be processed according to the process classification, which can be divided into two categories: flat labels and satin labels.

Flat sign:

The cloth label is like a cloth structure, and it is simply interwoven up and down with one warp and one weft, which is called a simple plane label. Generally speaking, the warp yarns are fixed, either black or white, so there are black flat and white flat. The pattern and color of the cloth label are mainly expressed by the weft yarn, and the color expressed should be different from the crossover effect of the warp yarn. Because general machines have restrictions on the types of weft yarns used, the colors that can be expressed are also limited, generally within 8 types. It can be seen from the above that the price components are: the width of the cloth label, that is, the amount of warp used; the length of the cloth label, and the length of each color along the warp direction. In order to express details and colors more abundantly, the weft yarns are doubled, which is called double-sided labeling. Except for washing and sizing, mostly flat double-sided labels are used. The cloth labels are all yarns to express the pattern, which must be different from the original graphic design, so it is impossible to make a large product without a small sample confirmation.

Post time: Feb-14-2023